- Home

- About

-

Products

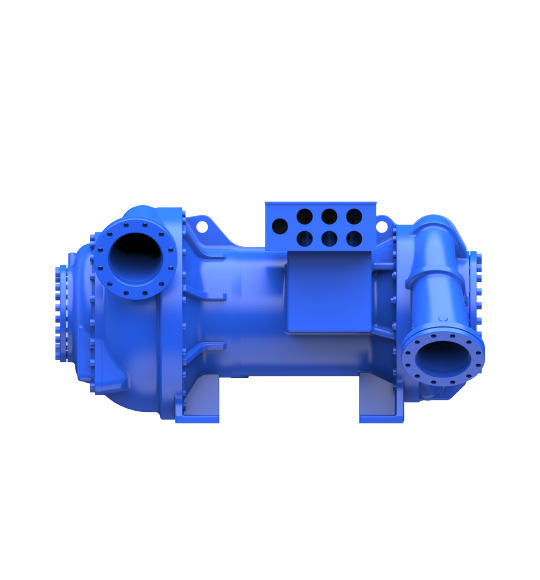

Screw Air Compressor

Air Conditioning Heat Pump

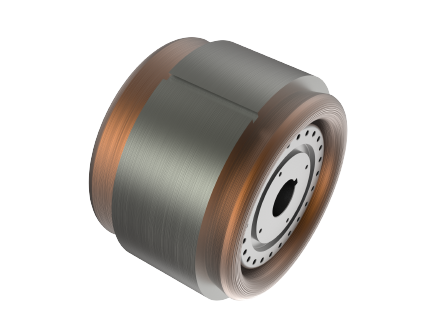

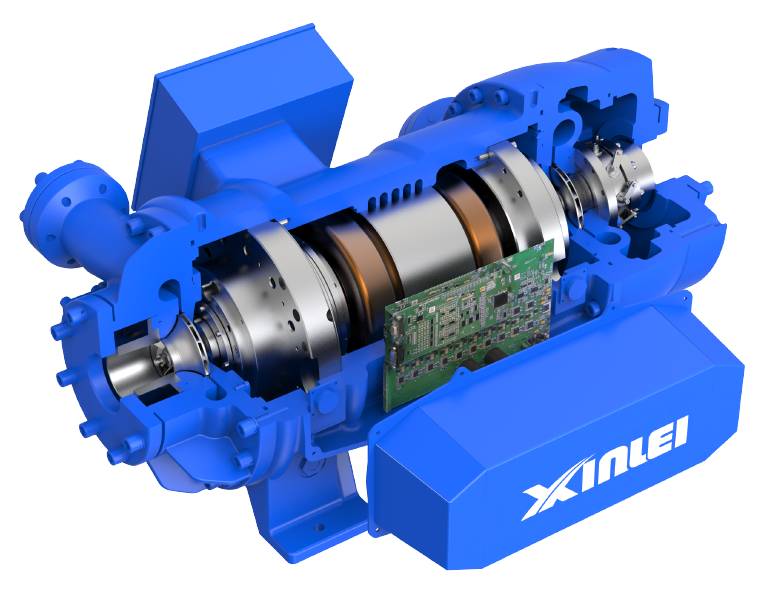

High-Speed Permanent Magnet Centrifugal Machine

Car-Mounted Air Compressor

Piston Air Compressor

OEM Business

Oil Cooling Series

Air Cooling Series

Water Cooling Series

There is currently no relevant data available!

-

Solution

- News

- Career

- Service&Support

- Contact